SilverAlloy A-60Ti-Active

Nominal Chemical

Composition

INTRODUCTION

Aufhauser SilverAlloy A-60Ti-Active is an active, brazing alloy that promotes wetting and good capillary action on several surfaces that would otherwise be difficult to join by brazing. The active components of this alloy promote wetting on, for example, ceramics and aluminum oxides (sapphire), diamond.

APPLICATIONS

Brazing with Aufhauser SilverAlloy A-60Ti-Active provides a reliable method of bonding ceramics, graphite, diamond, tungsten carbide, copper, kovar, nickel, nickel alloys, carbon steels, stainless steels.

GENERAL INFORMATION

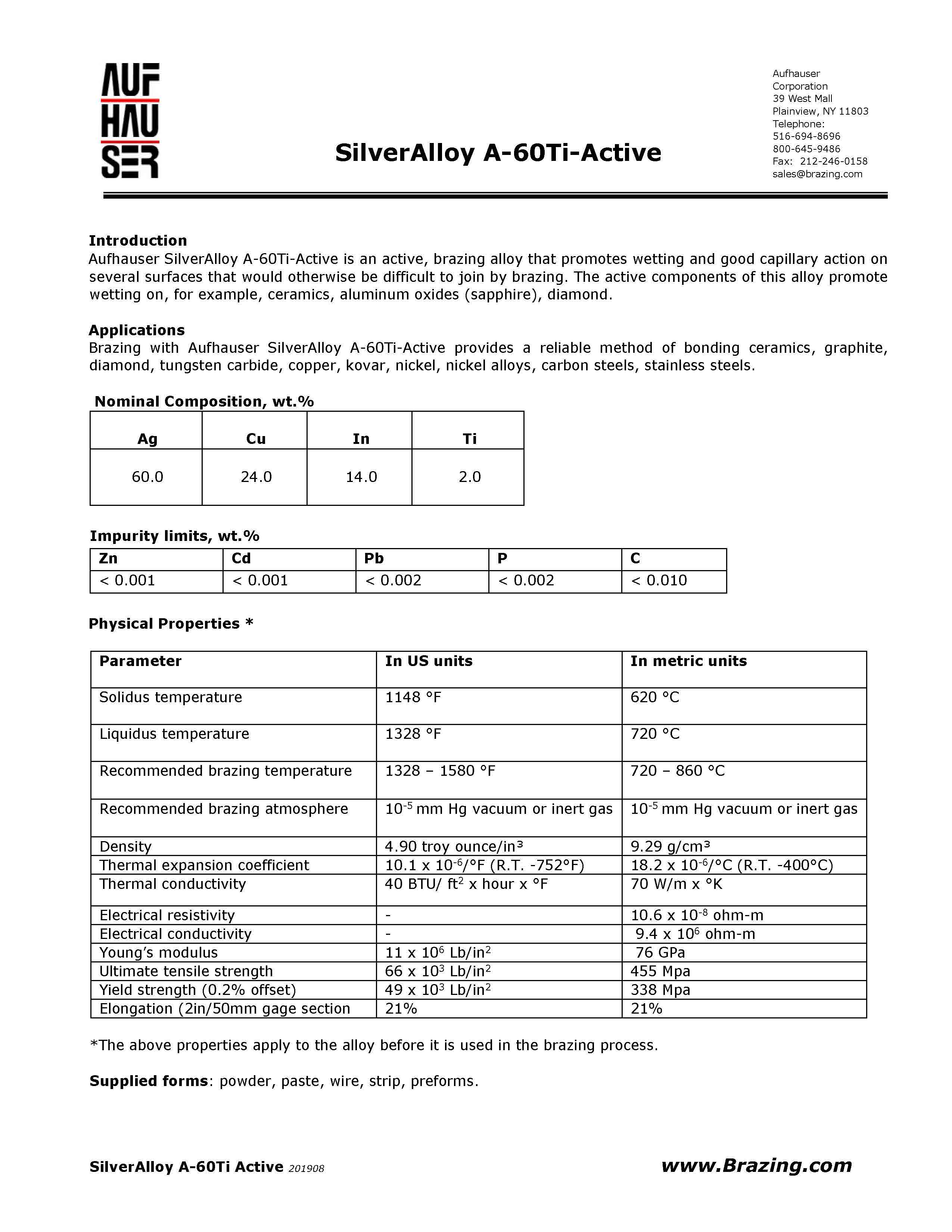

Chemical Composition (wt %)| Silver | Copper | Indium | Titanium |

|---|---|---|---|

| 60 | 24 | 14 | 2 |

| Zn | Cd | Pb | P | C |

|---|---|---|---|---|

| < 0.001 | < 0.001 | < 0.002 | < 0.002 | < 0.010 |

ADDITIONAL INFORMATION

PHYSICAL and MECHANICAL PROPERTIES*

| Solidus | 1148°F | 620°C |

| Liquidus | 1328°F | 720°C |

| Recommended Brazing Temperature | 1328-1580°F | 720-860°C |

| Recommended Brazing Atmosphere | 10-5 mm Hg vacuum or inert gas | 10-5 mm Hg vacuum or inert gas |

| Density | 4.90 troy ounce/in3 | 9.29 g/cm3 |

| Thermal Expansion Coefficient | 10.1 × 10-6/°F (R.T. -752°F) | 18.2 × 10-6/°C (R.T. -400°C) |

| Thermal Conductivity | 40 BTU/ft2 × hour × °F | 70 W/m × °K |

| Electrical Resistivity | 10.6 × 10-8 ohm-m | |

| Electrical Conductivity | 9.4 × 106 ohm-m | |

| Young’s Modulus | 11 × 106 LB/in2 | 76 GPa |

| Ultimate Tensile Strength | 66 × 103 LB/in2 | 455 MPa |

| Yield Strength (0.2% offset) | 49 × 103 LB/in2 | 338 MPa |

| Elongation (2 in/50mm gage section) | 21% | 21% |

* The above properties apply to the alloy before it is used in the brazing process.