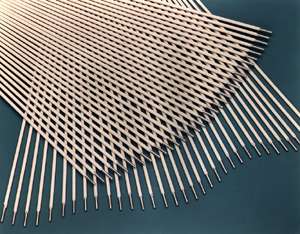

Stainless Steel Flux Cored

Aufhauser Flux Cored Stainless Steel Wires are precisely formulated for all position welding versatility with exceptional performance at high speed deposition rates.

Aufhauser Stainless Steel Flux Cored Wires yield consistently high performance and productivity for trouble-free welding of the stainless steels, aluminum, copper-base alloys, magnesium and carbon steels.

Aufhauser Stainless Steel Flux Cored Wires are precisely formulated for all position welding versatility with exceptional performance at high speed deposition rates. It is economical, as 100% CO2 can be used as the shielding gas, even in the vertical-up and overhead positions. Arc action is smooth and stable; also, the slag peels easily (less cleanup time). Operator appeal is a plus factor.

| E308LT-1 | Used for all-position welding using standard MIG welding machines. It has smooth bead appearance, and a stable arc that provides minimal spatter. Most frequently used for base metals of similar composition such as AISI Types 301, 302, 304, 305 and 308. |

|

| E309LT-1 | With a high deposition rate, E309LT increases efficiency. Recommended for welding similar alloys in wrought or cast form; occasionally, to weld Type 304 base metals when severe corrosion conditions exist; and, at times, welding dissimilar steels. |

|

| E316LT-1 | The E316LT-1 also increases efficiency because of high deposition rates. It is used for welding similar alloys (containing about 2% molybdenum); also for high temperature service applications (the presence of molybdenum provides increased creep resistance at elevated temperatures). |

All wires listed are used with standard MIG welding machines.