SuperBlue Covered Electrode

Nominal Chemical

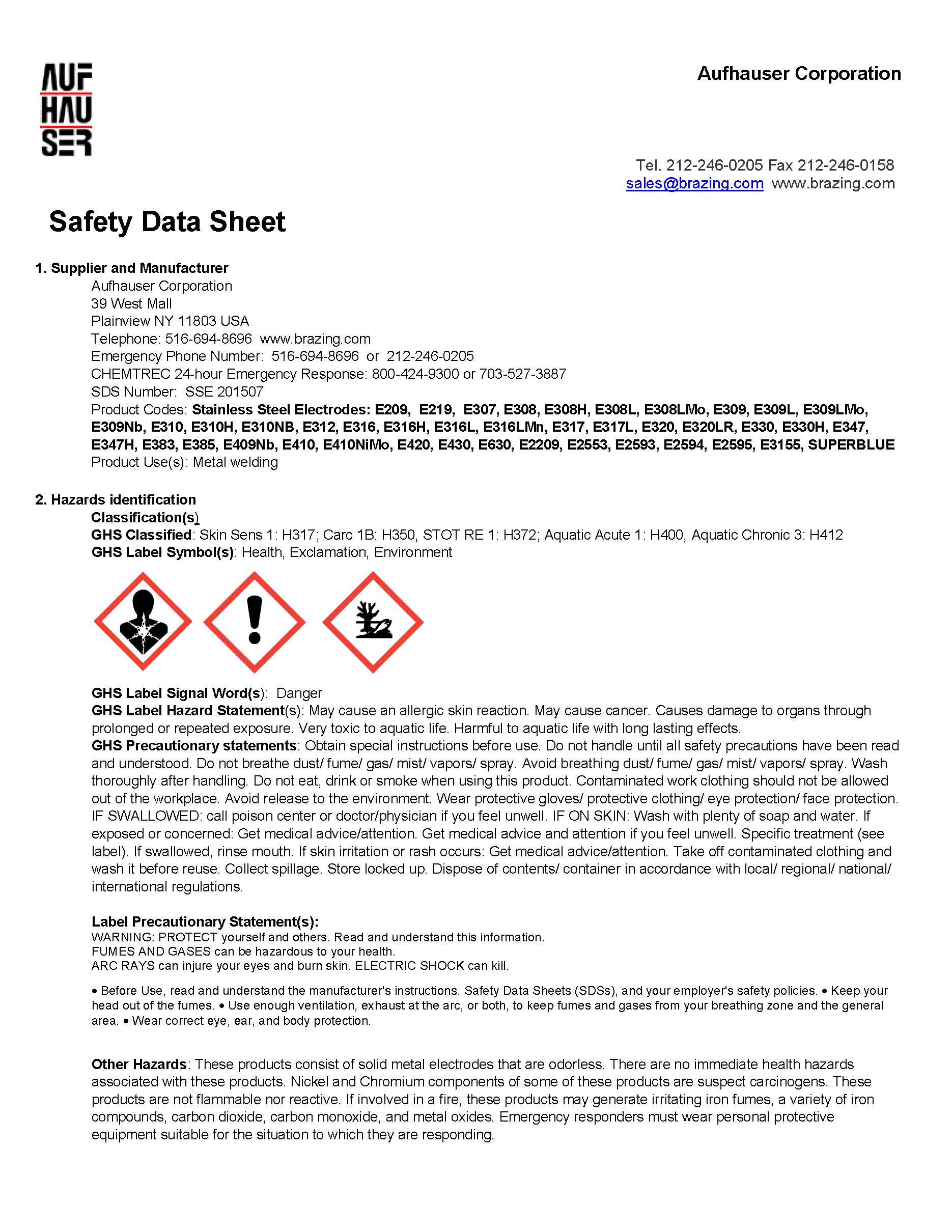

Composition

INTRODUCTION

Aufhauser SuperBlue covered electrode is a versatile, multi-purpose electrode, suitable for welding wrought and cast alloys such as high carbon, tool steels, stainless steels, spring steels, manganese steels and dissimilar steels. This alloy gives a two-phase weld deposit with substantial amounts of ferrite in an austenitic matrix. This alloy has excellent impact and frictional resistance with high heat resistance and mild abrasive resistance.

APPLICATIONS

- Wrought and cast alloys

- Problem steels such as high carbon, tool, stainless, spring, manganese steels

- Dissimilar steels

GENERAL INFORMATION

Typical Chemical Composition| Carbon | Chromium | Nickel | Molybdenum | Manganese | Silicon | Phosphorus | Sulfur | Copper | Iron |

|---|---|---|---|---|---|---|---|---|---|

| 0.15 | 28-32 | 8.0-10.5 | 0.5 | 0.5-2.5 | 1.0 | 0.04 | 0.03 | 0.5 | Rem |

Note: All values are maximum percentage, unless shown in range.

PHYSICAL and MECHANICAL PROPERTIES

| Tensile Strength | 120,000 psi |

| Yield | 85,000 psi |

| Elongation, min. % | 35 |

| Avg. Impact Strength % | 29 |

Recommended Welding Parameters

| Wire Diameter | Amps |

| 3/32" | 40-80 |

| 1/8" | 70-110 |

| 5/32" | 95-145 |

| 3/16" | 145-200 |

SPECIFICATIONS MEET or EXCEED |

| ANSI/AWS A5.22 (E312) |

STANDARD SIZES AND DIAMETERS |

||

| Diameters | 3/32", 1/8", 5/32", 3/16" | |