70S-3 Mild Steel MIG Wire

Nominal Chemical

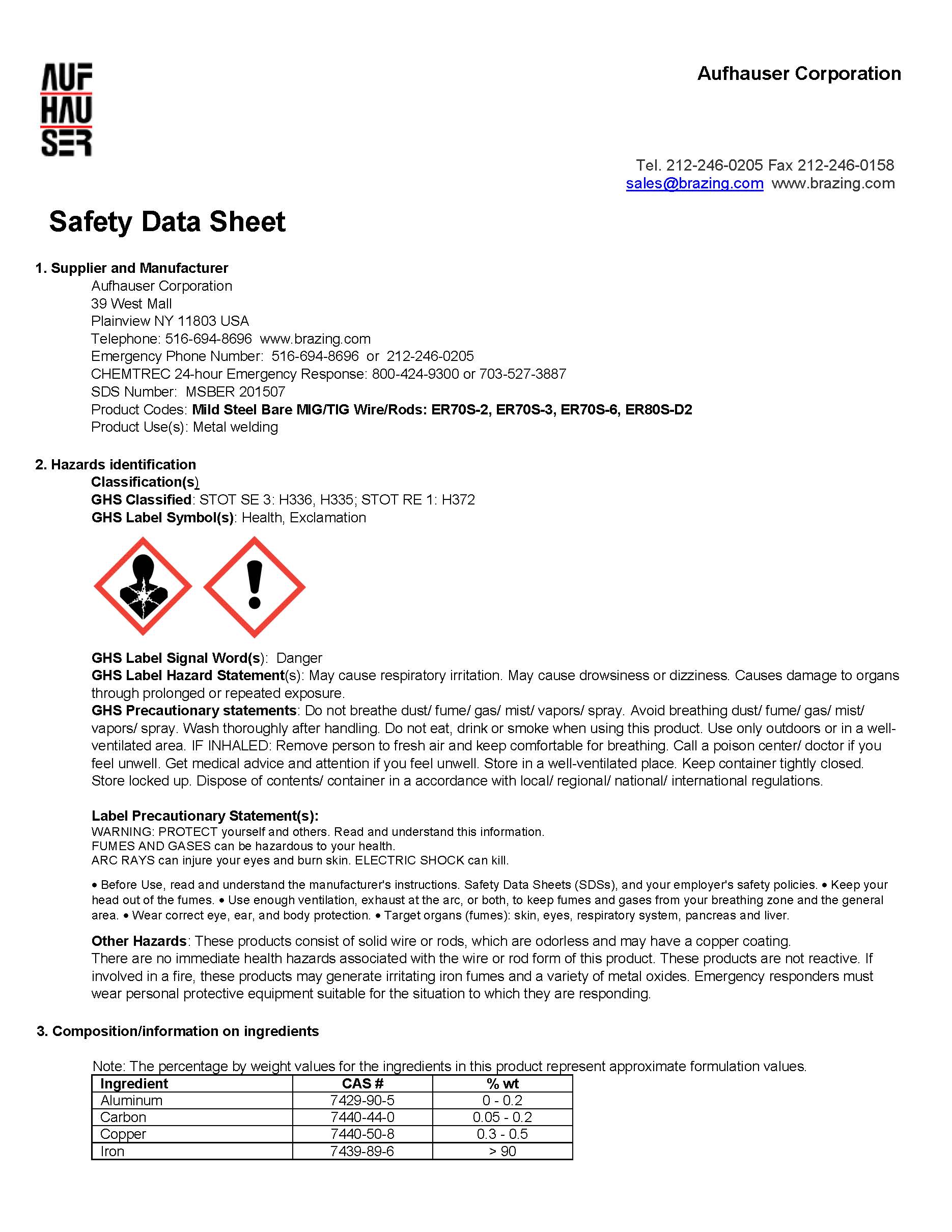

Composition

REFERENCES

Mild Steel Alloys GuideINTRODUCTION

Aufhauser 70S-3 is a silicon and manganese deoxidized wire for mild and low alloy steel general purpose fabrication. A well balanced silicon and manganese content permits its use with CO2, argon-oxygen mixtures, or mixtures of the two. This wire may be used for short-circuiting arc (dip-transfer), buried arc, as well as spray transfer arc processes. Aufhauser 70S-3 produces quality welds with rimmed steels, better welds on killed steels. It yields an almost slag-free deposit, which does not require cleaning for many applications, thereby providing low plate preparation costs, good bead appearance and welder satisfaction.

APPLICATIONS

- Welding steels with dirty or rusty surface

- (UNS numbers K02600, K02801, K02001, K02700)

- Single-pass welding of killed, semi-killed, and rimmed steels

- May be used for some multi-pass applications

GENERAL INFORMATION

Chemical Composition| Carbon | Manganese | Silicon | Phosphorus | Sulfur | Copper* | Other** | Iron |

|---|---|---|---|---|---|---|---|

| 0.06-0.15 | 0.90-1.40 | 0.45-0.75 | 0.025 | 0.035 | 0.50 | 0.50 | Rem |

* The maximum weight of copper due to any coating plus the residual copper content in the steel shall be 0.50.

** Other elements (Ni, Cr, Mo and V) may be present as trace residuals and collectively are not to exceed 0.50.

PHYSICAL and MECHANICAL PROPERTIES†

| Tensile Strength | 81,000 psi |

| Yield | 67,900 |

| Elongation, min. | 29% |

| Average Impact Strength | 29% |

† Determined with 100% CO2 shielding gas

SPECIFICATIONS MEET OR EXCEED |

| ANSI/AWS A5.18 (ER70S-3) |

STANDARD SIZES AND DIAMETERS |

| Diameters (inches) |

| 0.023, 0.030, 0.035, 0.045 |

.jpg)